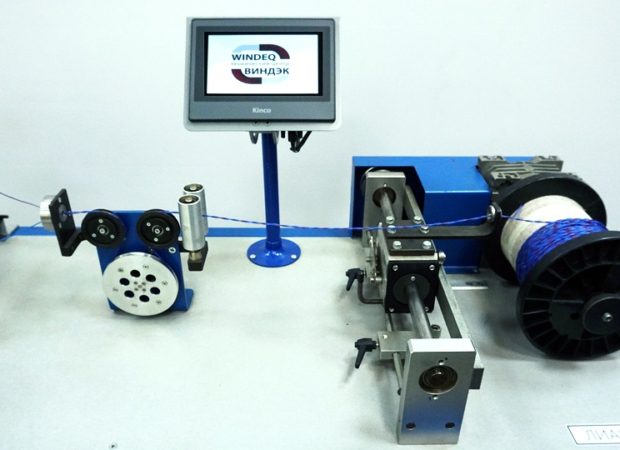

Liana-02 – Wire Twisting Machine, made by WindEq TC, LLC, Russia

Description | Advantages | Technical features | Application options

Description

WindEq wire twisting machine – Liana-02 is designed to twist two or four wires into a long twisted harness while simultaneously winding it on the master reel.

Automated Liana-02 machine twists two or four wires into a long twisted harness. The presence of the operator is not required upon rereeling.

Quality of twisting is controlled by the control system and ensured by the design of the machine. Force of twisting of cores and insulation is compensated for by rotation of the payoff reels without changes in their position in space. Stability of the length of twist is ensured by the controller-based control system, while the speed of reeling of the finished twisted pair is adjusted depending on the speed of its formation. The machine provides for wire rereeling from the coil onto the payoff reel.

Advantages

- Ease of control

- No core and wire insulation kinking upon twisting

- Automated and manual setting of the length of twisting depending on the diameter of the wire

- Automated measurement of length of the twisted harness

- Possible wire rereeling

Technical features

Scope of application

The machine is designed to produce harnesses including twisted pairs of wires. Twisted harness produced by the machine is convenient for use upon forming complex harnesses of various nomenclatures in products of the aerospace and the military industries. Possible types of wires for twisting: МГТФ, МС, ПВАМ, НВ, МГШВ, ПВ, and other installation and connecting wires.

The machine features sensors of wound harness tension and supply failure (end). Use of Mitsubishi FX controller ensures reliability and uninterrupted operation. The touch control panel with an intuitive interface allows you to set the control modes and the parameters of the twisted wires.

Service

WindEq TC provides the users of equipment with service support:

- personnel training

- routine maintenance

- supply of spare parts

- assistance in provision of process solutions for production tasks