Production

WindEq Technical Center has been manufacturing industrial equipment for the electrical, energy, petrochemical, electronic, and automotive industries since 2006.

The company has a team of high-class specialists and a unique production experience. It makes it possible to organize a full cycle of the project implementation:

- development

- manufacture

- testing

- assembly

How we work

First, we study the customer’s assignment, prepare a technical offer, a sketch and a layout, create a detail design, and submit it to the production.

Then, preparation of production follows: we prepare material and components, manufacture parts and assembly units, and assemble the product.

The final stage is a mandatory control of the finished equipment for compliance with the design documentation and the customer’s requirements.

We produce both single products and small batches.

Structure of Production

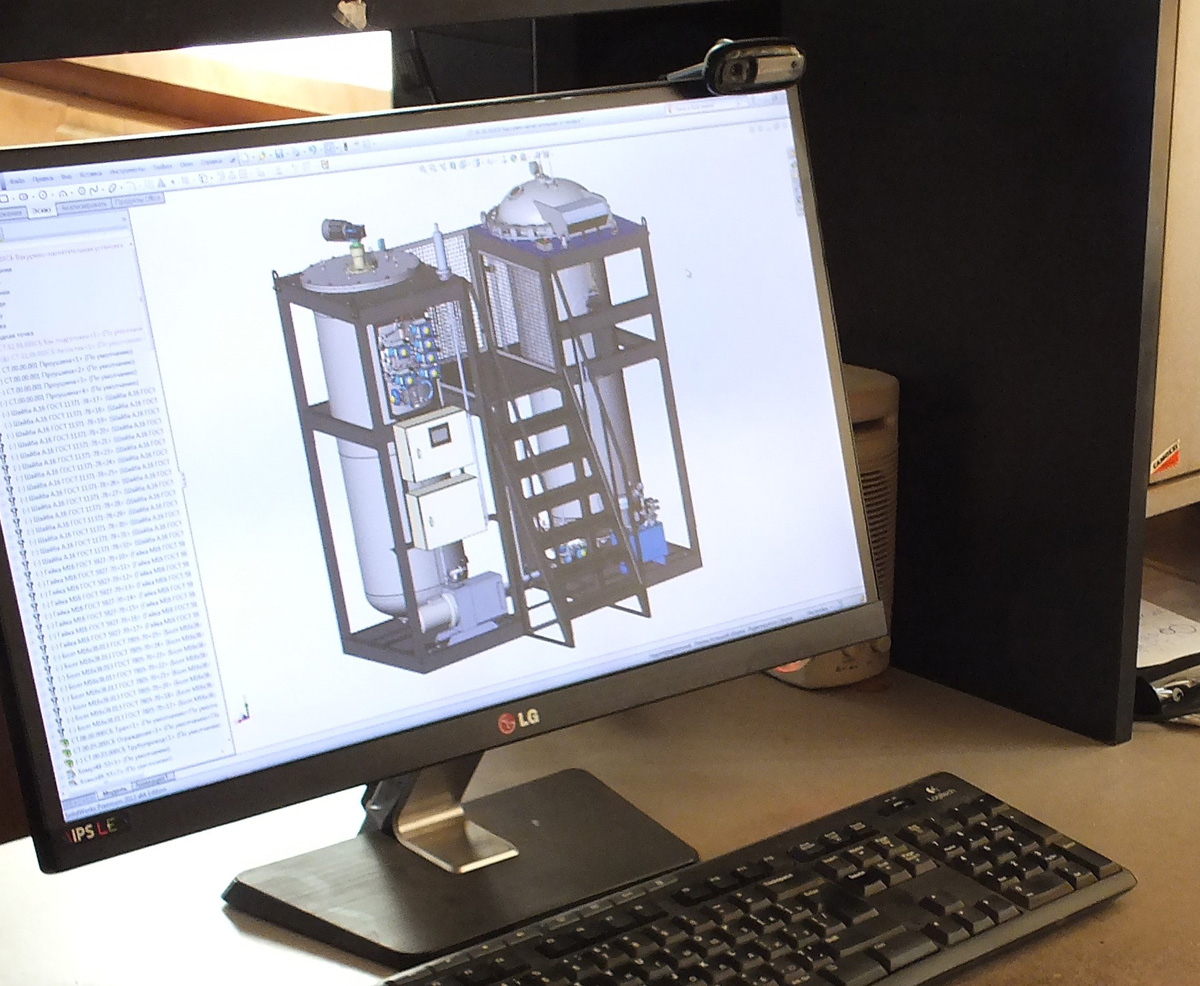

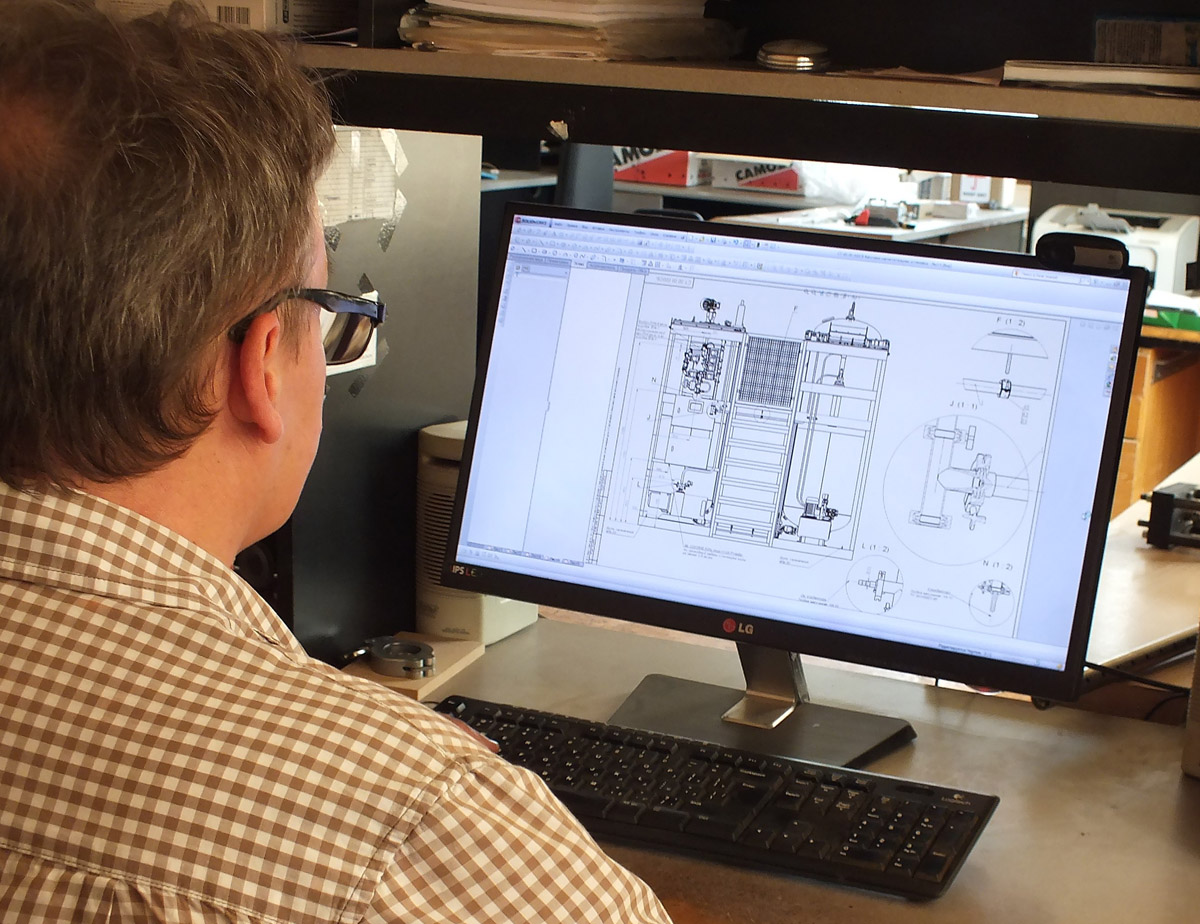

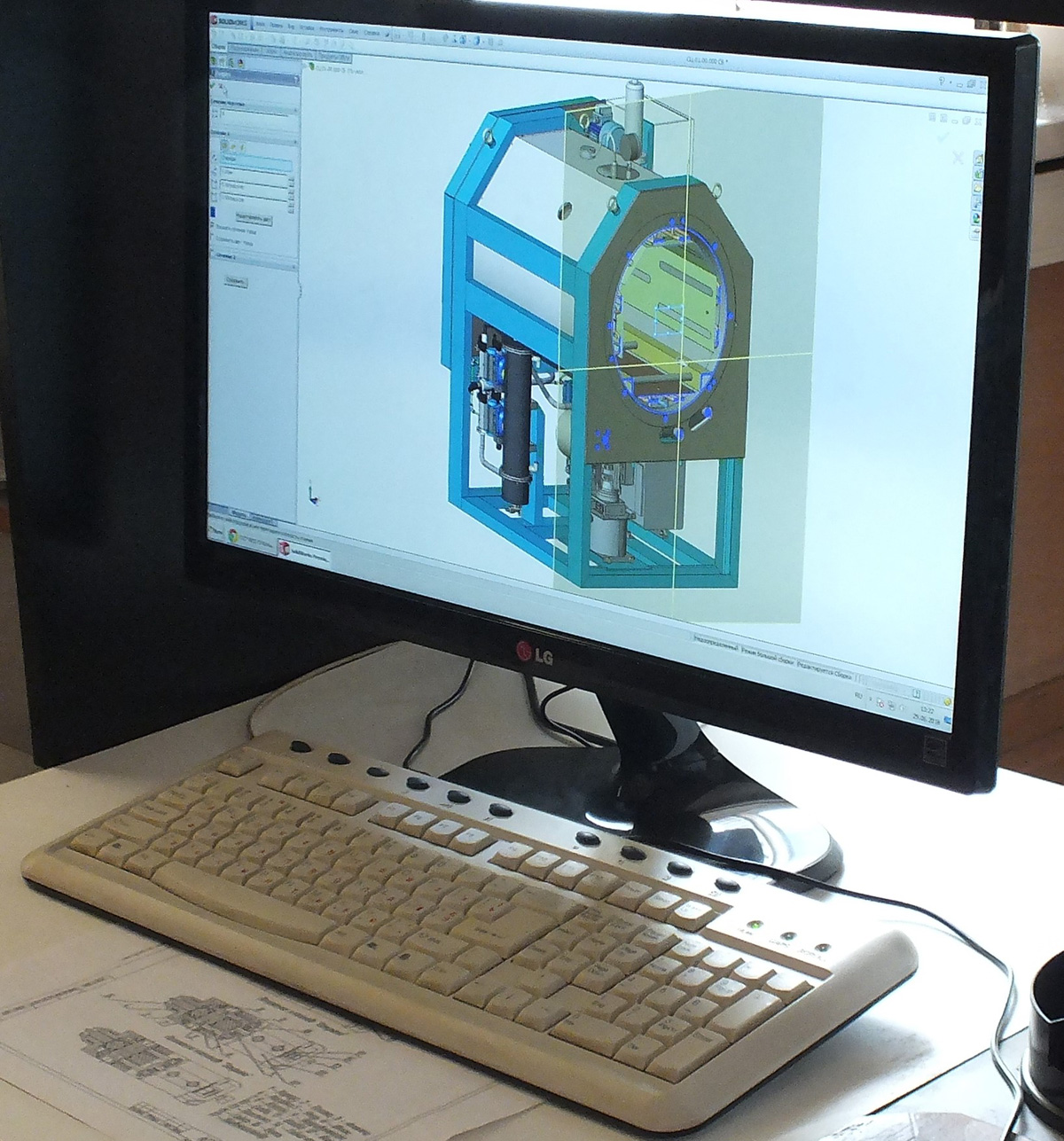

Design Office

The office employs mechanical engineers, system design engineers, and programmers. They have not only design, but also production and technological experience, participate in the processes of production of components for equipment, their assembly and adjustment.

Therefore, we develop equipment that will solve the production tasks of the customer while ensuring maximum efficiency.

Production Floors

Pilot production with a set of general-purpose equipment produces exclusive plants for the following areas:

- industrial automated autoclaves

- specialized plants for compound pouring

- specialized winding equipment

- wire processing equipment

- vacuum equipment

The Tool Maintenance Department ensures manufacture of parts, on which increased accuracy requirements are imposed.

We are not limited to our own fleet of equipment: large parts are processed at the related enterprises.

Our Advantages

- Flexibility

- We develop non-standard equipment for tasks of any degree of complexity.

- Unique knowledge and modern technology

- Our designers come from ROSATOM, large enterprises of the defense and mechanical engineering industries. The design team has experience in designing vacuum equipment, thermal and low-pressure chambers.Equipment undergoes software modeling for temperature conditions and loads. Layouts and drawings are drafted using modern CAD tools such as Solid Works, AutoCAD, Kompas.

- Strict production quality control

- All equipment passes testing and technical control for compliance with the quality standards.

The solutions offered by WindEq TC are based on many years of experience, continuous monitoring of advanced technologies, and a thorough study of customer’s requirements. We are ready to help customers to master production of new products, upgrade production, and ensure successful business development.